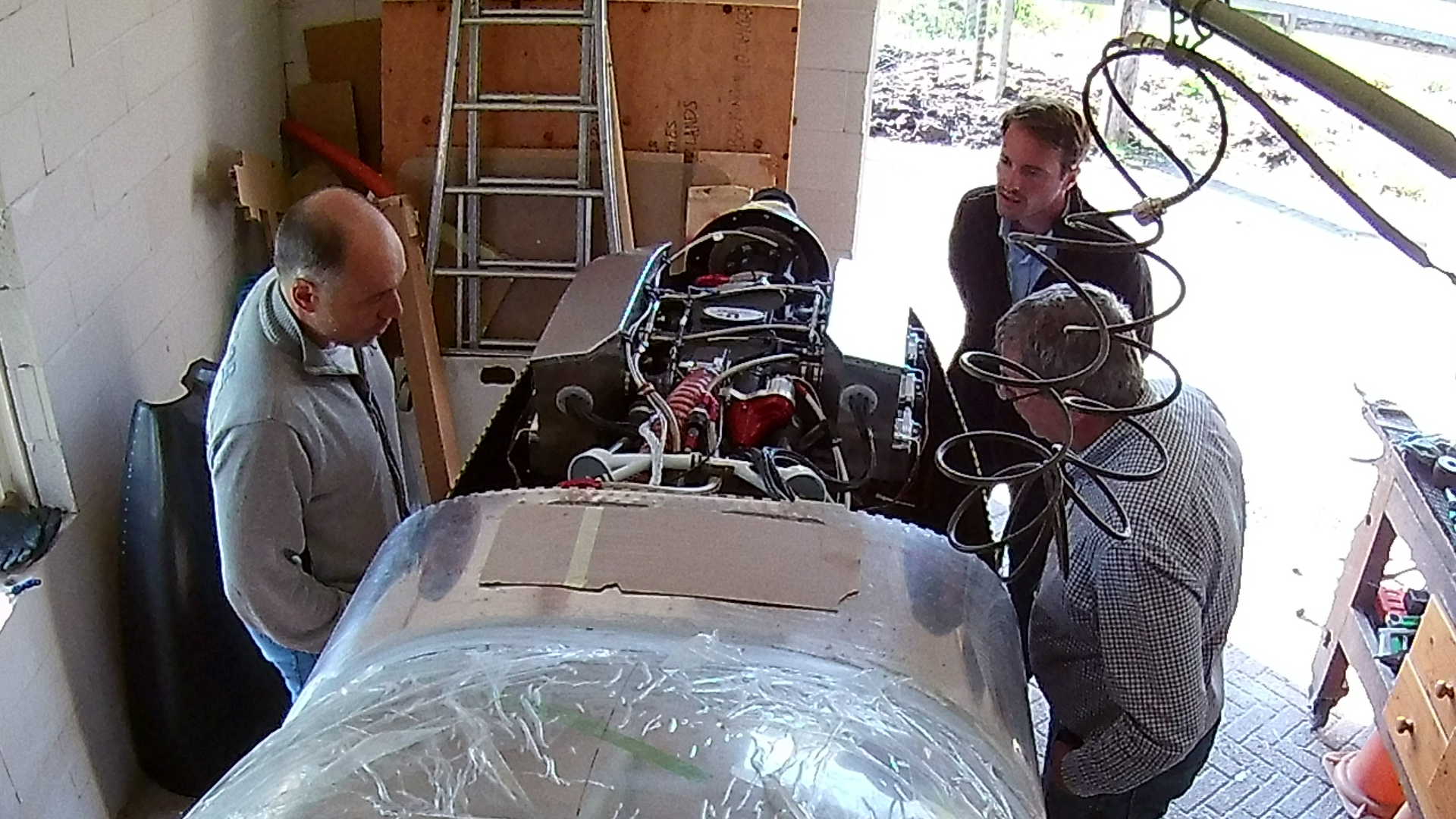

I was really honored, when Evelyne of ULPower called me to ask me if Patrick, the managing director of ULPower in Belgium, could visit me regarding my RV-7 ULPower 520iSA setup. ULPower is developing a Turbo version of the 520 specifically with the RV-7 in mind. ULPower wants to check if there is enough space under the cowl of an RV-7 for an additional Turbo and Intercooler.

Of course I was happy to open up my cowl for ULPower to checkout my setup. I was filled with pride when Patrick and Jakob gave me compliments on my engine installation. Since they are the experts on this topic.

They check out the various possible locations for a Turbo and Intercooler and they made several photo’s, took measurements and created sketches.

They also gave me extra tips on how to improve installation and we discussed several options. For me this visit was already a big success.

Patrick also discussed the Air intake for the engine. I wasn’t sure what the best (achievable) setup would be, but together with Patrick and Jakob we figured out the best solution.

It’s really great when you can have an in-depth conversation between you as a builder, with one of the designers of the engine that you use. I realize this is very rare and treasure this opportunity.

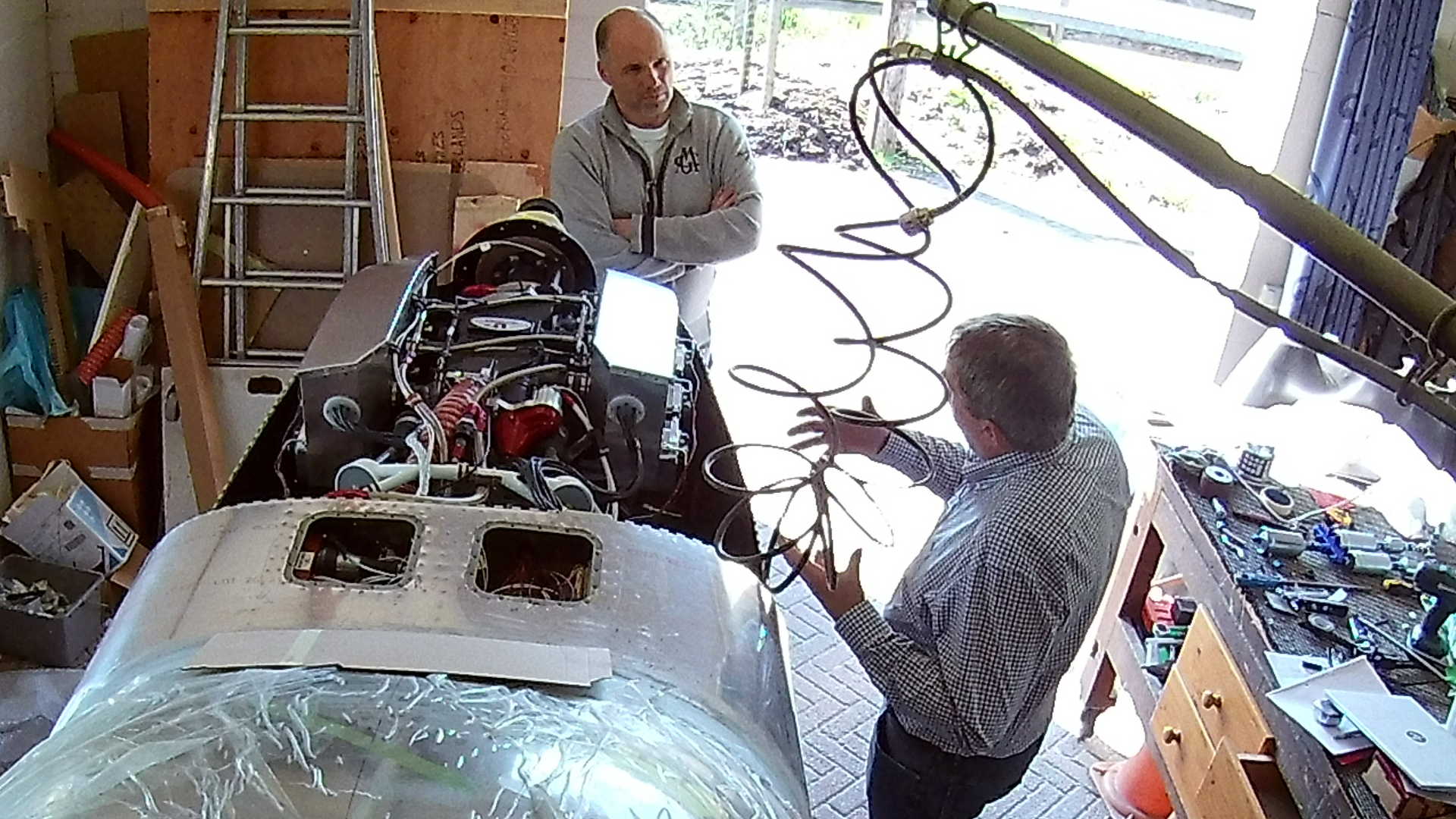

Together with Patrick and Jakob, we did a check of my avionics and alarm lights, which checked out ok. However the CAN-BUS communications from both the MGL RDAC ULP and MGL RDAC XF to my MGL XTreme EFIS and EMS did not work correctly. When connecting the laptop and running the analysis software, the ECU was OK.

Again, I’m delighted that ULPower visited my workshop and I hope they can make a big success with the Turbo version of the UL520. If I had to select an engine at this point in time I would consider that engine, although it is considerable more expensive and heavier.

Earlier this year, when I picked up my custom cowl at ULPower, they were testing the UL520T and I must say it looked (and sounded) magnificent.

Working on the CAN-BUS, it turns out that the drawings of the connector is wrong.

I didn’t purchase a pre-built wiring harness, because those are expensive and the components are cheap. However if the plans are incorrect, it takes some time to fix it.

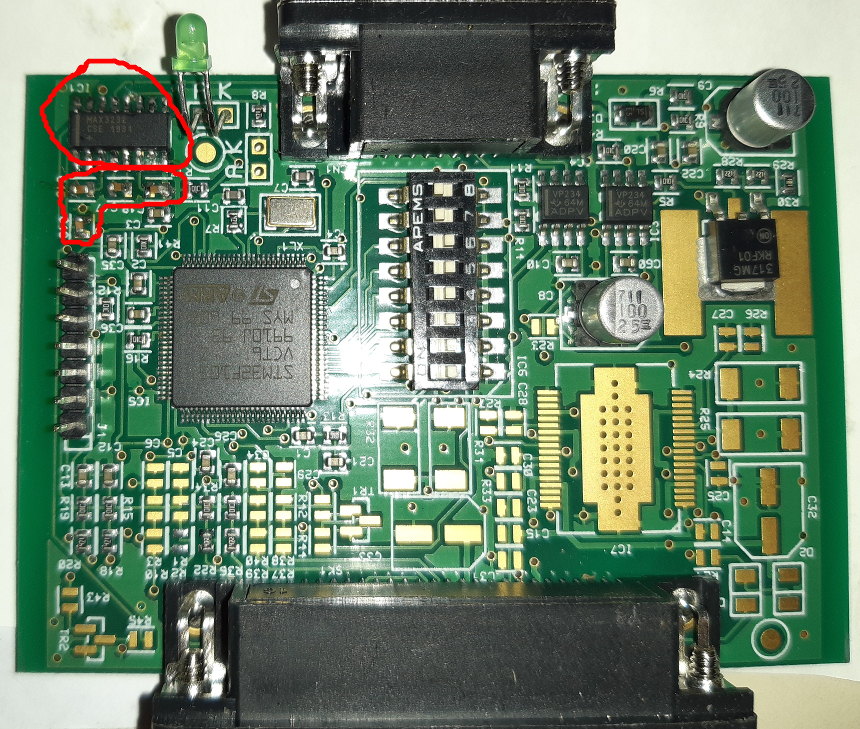

Here is a view of the (stock) MGL RDAC ULP. For some reason MGL does not include the RS-232 chip (which costs less then €2,-), so I had to solder this myself, including 4 minuscule capacitors. All SMD devices, so that’s just great when you’re over 50 and your eyes can hardly detect those components let alone solder them nicely.

After fixing the CAN-BUS, I continue with the Fuel system. Unfortunately I have to crawl into the forward part of the ‘cramped’ cockpit to work on it.

The most challenging part of the fuel system is the most forward tube from the Fine Fule Filter to the Bulkhead through the Firewall. I have all the ‘parts’ of the fuel system in the cockpit on the floor. I hindsight I might have improved maintenance by moving the Fine Filter to the engine side of the Firewall. This is however the most compact setup, which I’ll probably regret at the first maintenance job after 15 hours of flying.

I didn’t use the ‘standard’ ULPower Fuel system. I did use the Filters and Pumps that come with the kit, but I decided to use different connectors, to make the whole construction fit the center part of the leg space.

Time: 6 Hours, Rivets: 0/0 (2021-05-02)

Time: 5 Hours, Rivets: 0/0 (2021-05-03)

Time: 6 Hours, Rivets: 10/0 (2021-05-04)

Time: 2 Hours, Rivets: 0/0 (2021-05-06)

Time: 5 Hours, Rivets: 0/0 (2021-05-09)

Time: 7 Hours, Rivets: 0/0 (2021-05-12)

Time: 6 Hours, Rivets: 0/0 (2021-05-16)