The Tanks need considerable time to prepare before they can be assembled. Besides the “normal” match-drilling, deburring, the Tanks also require specific attachment angles , which need to be fabricated from Aluminum profiles.

Here I work on the Tank Attach Angle of the Right wing Tank on the most inboard rib. The build plans don’t say much more than “create tank attach angle”. The drawing (DWG16A) does not show much more than a 1/2 scale sketch.

Again, I work in parallel, so after finishing the right one I started on the Left Wing. The “mirroring practice is getting better and better. I tend to screw up less.

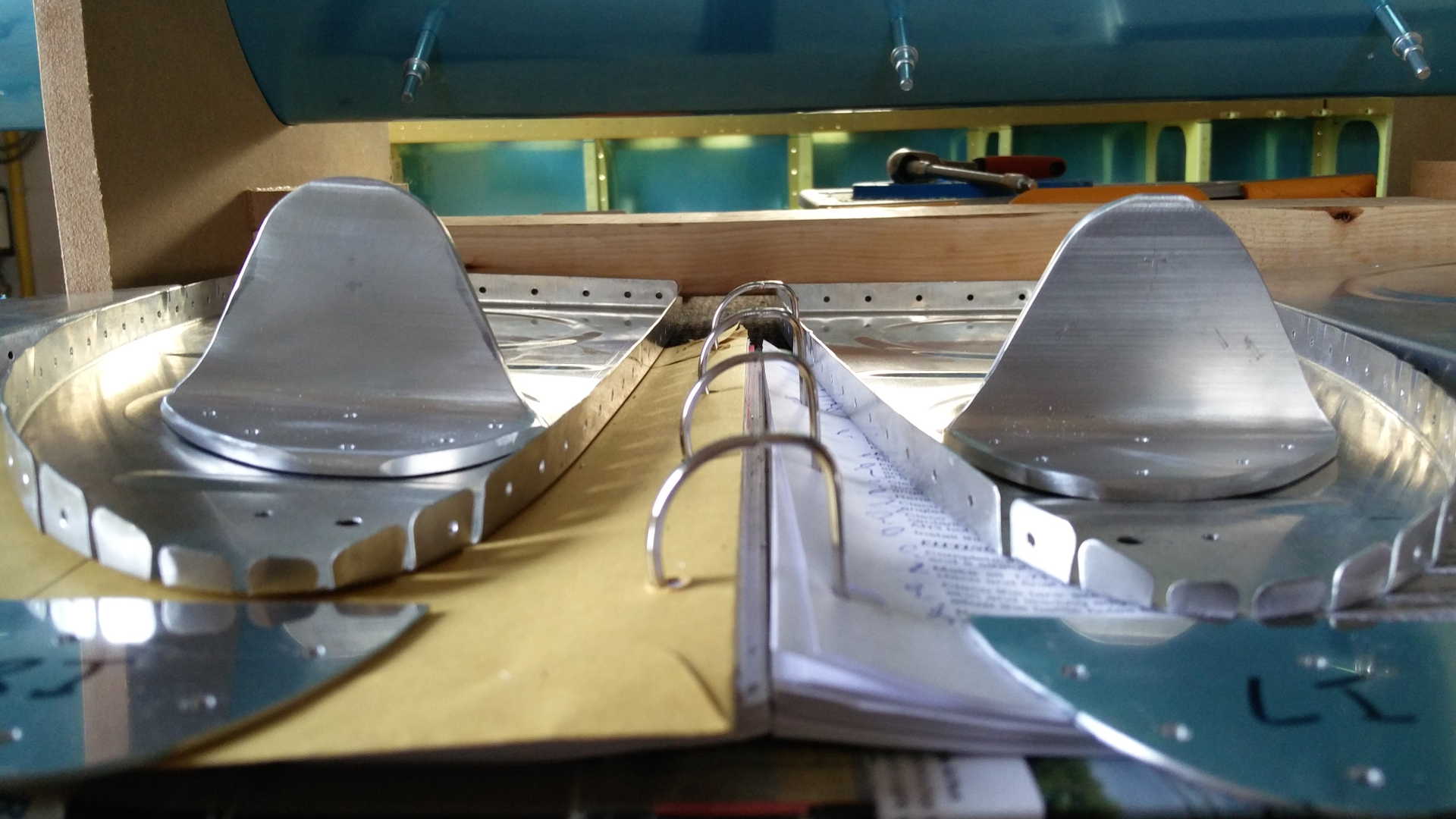

Here are the results of both Tank Attach Angles. I’m really satisfied with the result, considering the thickness of the material.

Here’s a view of the part that will probably go into the fuselage (assumption, I didn’t receive the fuselage plans and drawings yet.

After using the cleco’s extensively for several times I spray WD-40 on them when I tidy up.

To match-drill the Tank ribs I cleco the wing to check if all parts fit.

The three platenuts in the main spar that attach the most inboard angle need to be riveted at this point. To me that looks sub-optimal, since there is less room. If I’d known this I would have done this during initial tank attach platenuts. The plans indicate to do it here, because you need to drill it with the holes in the main spar as guide. So I get that, but I would still install the platenuts earlier and drill the holes “through” the platenuts with a smaller drill and a small pipe. This way you protect the platenut and you can enlarge the holes later.

All the rivets I had to reset where related to these platenuts. Every time when I use the rivet gun (instead of the squeezer), I tend to forget to hold the bucking bar correctly.

Time: 3 Hours, Rivets: 0/0 (2018-08-15)

Time: 4 Hours, Rivets: 12/5 (2018-08-19)