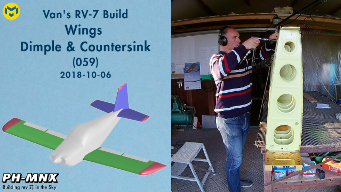

In between sealing and riveting Tanks, I took the time to dimple and countersink the wings. The main spar should NOT be dimpled, as the material thickness is to high.

It will either fail or you will damage the main spar.

Since the material is thick enough it is easy to countersink.

The ribs on the contrary can easily be dimpled. In this case with the every so beautiful squeezer. If you would try to countersink the ribs that would go horribly wrong because of the thin material.

The rear spar of the wing is a special case, the thickness of the Aluminum is somewhere between the ribs and the main spar. You can dimple it, but it will not be as “deep” as the rib dimple. So I do both dimple AND countersink the rear spar. Although the countersinking doesn’t take away that much material.

Afterwards I spot-primed all the countersunk holes. Again probably not necessary, but better save than sorry. Also on the Sunday I primed the leading edge skin and some trailing edge parts I forgot earlier.

Time: 5 Hours, Rivets: 0/0 (2018-10-03)

Time: 3 Hours, Rivets: 0/0 (2018-10-06)

Time: 3 Hours, Rivets: 47/0 (2018-10-07)