Finally I received the Fuselage kit. It’s always hard to predict when you will finish the previous kit and when to order the next. Take into account a 2 months lead team and 2 weeks of shipping when ordering. As you can see in the back the wings are nearly done and also the flaps and ailerons are done.

The Fuselage comes in a single 140kg crate. I’ve created a cart to transport the crates from the truck to the workshop. Also many trucks don’t have a forklift, so the cart comes in handy. Opening the crate was easy as 1 side and the top nearly fell of on arrival.

As you can see, one side of the crate is severely damaged, so I checked before signing the paperwork. Turned out they really do a great job at Van’s. Even if a forklift driver screws up in the harbor, the kit is still ok.

How is that possible? Paper, lots of paper.

Not just the subkits, but also between the subkits. In this case I’m particularity glad Van’s did that, else I probably had some damage.

After unpacking a part or subkit, you have to check the Inventory list to see if everything is in the crate. On first site it seems impossible, but the box on the floor actually is 75% of the Inventory list.

Last summer I created a simple attic, where I can store the parts. On the left side I store skins and aluminum parts. On the right side I keep other parts, such as steel parts, hoses and in this case a tail wheel.

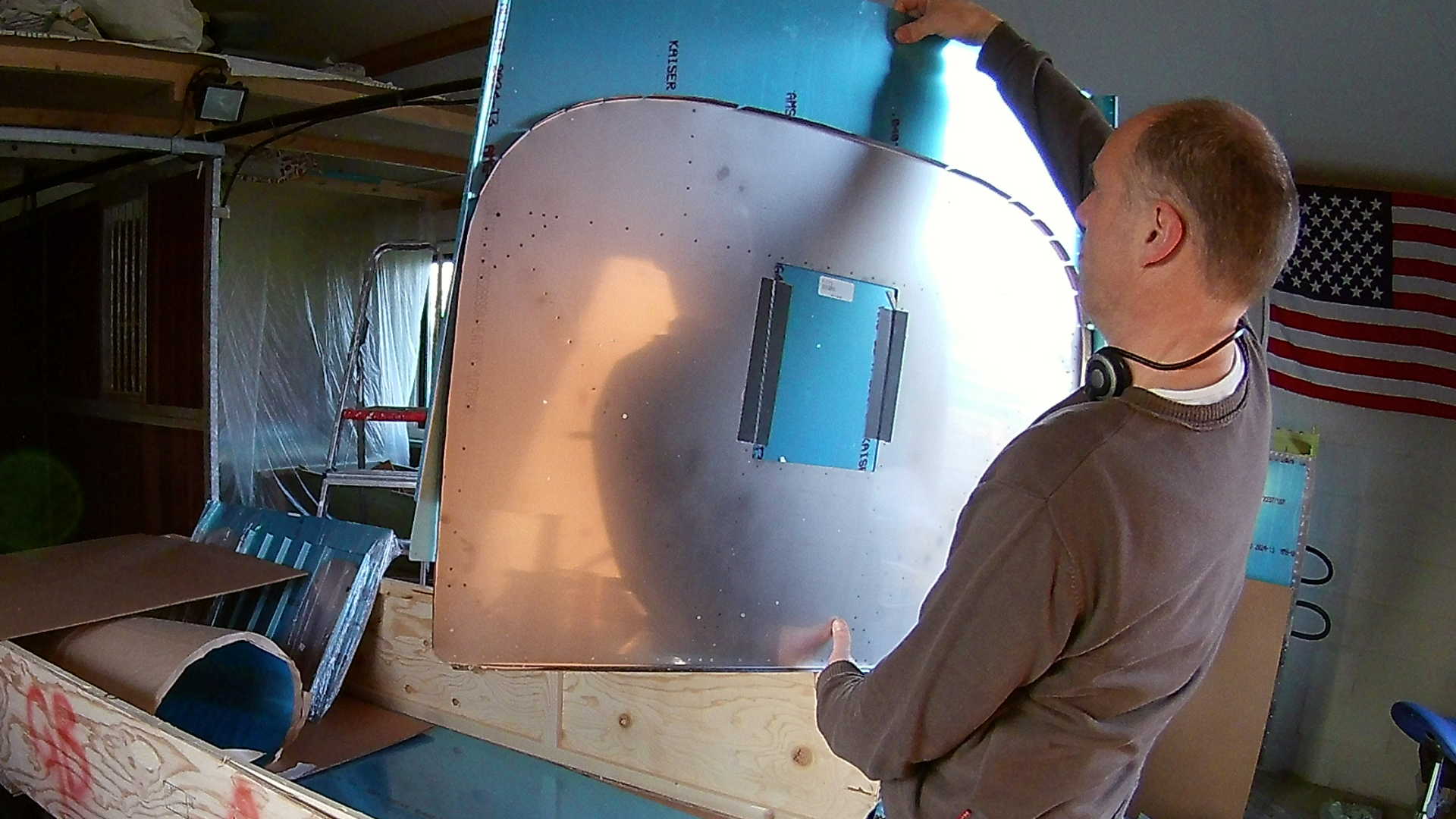

Aha, the firewall forward. According to the plans a steel plate that will ruin your drills in a second. I ordered some spare Cobalt drills and some drill-oil.

There are many bags with small parts in the kit, such as bolts, rivets, nuts, washers and nutplates. I found that the best way is to get them out of the bags and put every type in its own bag. The bags of Van’s are created for specific parts of the kit. However some type of bolt or nut can be in five bags. Better spend a few hours extra during inventory and make them easy accessible during building.

Time: 7 Hours, Rivets: 0/0 (2019-04-18)