While working on finalizing the wings, I interjected the work with preparing the flaps. Main reason is that for closing the wings, it is really handy to work with two people on it. So when my dad is not available, I work on the flaps.

This results in about 7 short seasons in the last 3 months where I worked en the flaps preparing them for priming.

Starting of as always with the deburring of the parts. In this case the lighting holes in the Flap Spars.

Instead of deburring the flenge sides with a file or sand paper, the Scotch Brite wheel is so much easier and delivers a better result.

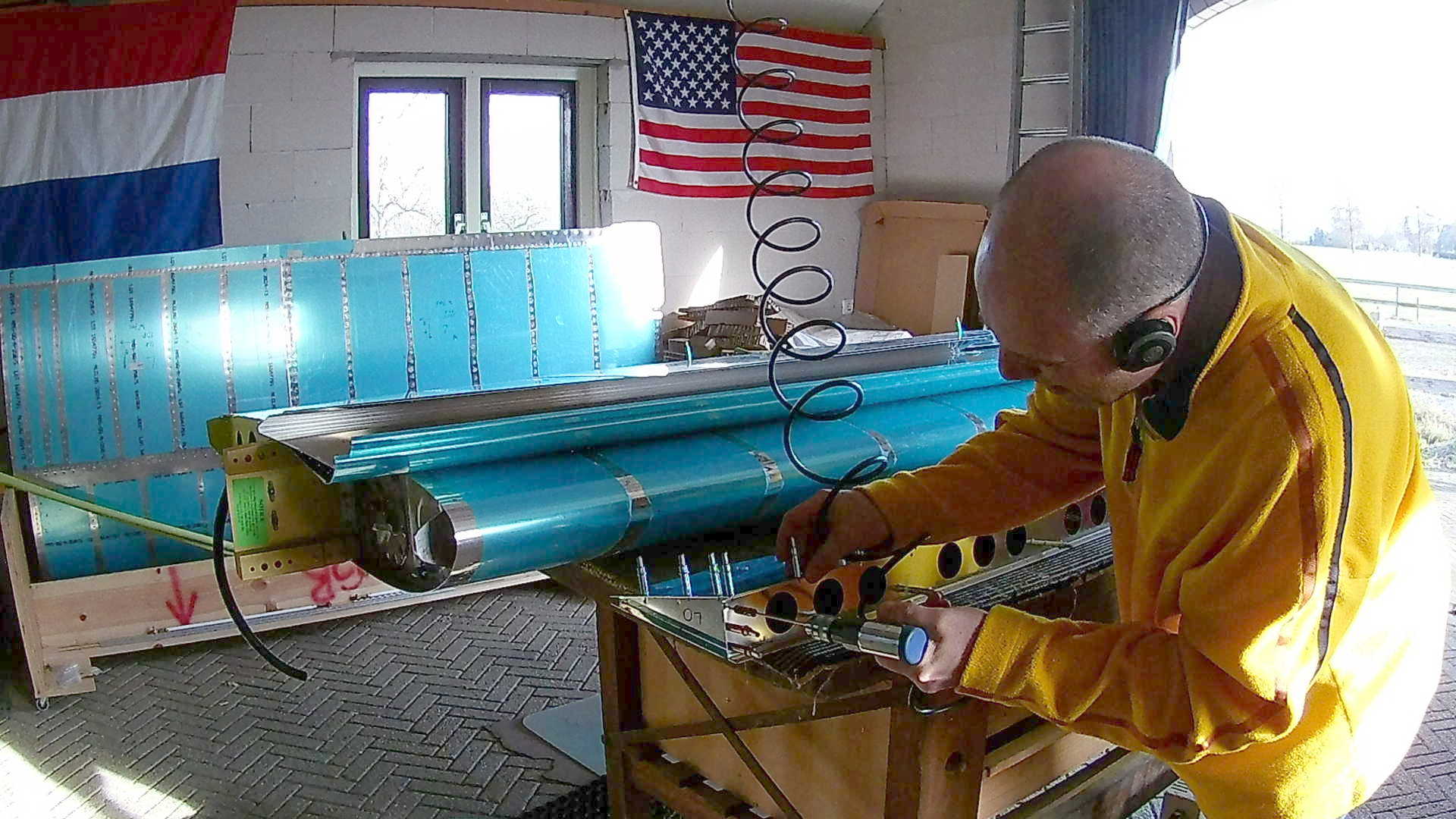

Assembling the flaps for match drilling. I work on left and right in parallel. The Wing where I’m also working on is also on the table.

Match drilling the spar to the end ribs of the spar. On this part there is some extra work as there are doublers to attach the flap drive to.

Here you can see the doubler of the Spar. There is also a doubler of the inner rib. Both will be riveted together to create a strong construction.

The finished result before priming that is. Now I have to detach every thing again and clean it up for priming.

Time: 5 Hours, Rivets: 0/0 (2019-02-06)

Time: 4 Hours, Rivets: 0/0 (2019-02-16)

Time: 3 Hours, Rivets: 0/0 (2019-02-20)

Time: 2 Hours, Rivets: 0/0 (2019-02-27)

Time: 2 Hours, Rivets: 0/0 (2019-03-02)

Time: 2 Hours, Rivets: 0/0 (2019-03-09)