The first item on the Fuselage list is preparing the firewall. The firewall is a steel plate that separates the engine from the cockpit.

I have to create a bracket from a thick angle piece. I had still a piece of the same angle from the Wing kit, so I started with that one.

I still think a band-saw is not necessary, but I must admit that the handsaw is not easy. You hardly ever need it, but when you do it sucks that I don’t have a band-saw. Maybe I do need to buy one. I’ll probbaly do it right after the last part I need it for.

Clecoing all the parts to the Firewall for match drilling. Steel has two properties that bite you. It’s sharp as a knife and you can kill your drill on it.

There is a recess in the Firewall, which is necessary for the oil filter and the governor (according to the manual). All these holes need to be dimpled, because the goal is to keep this (forward) side of the Firewall flush.

One stiffener must be created from Aluminum angle. Unfortunately the similar angle I had from the Wing kit is too short.

Let’s drill all the holes. For match drilling I use the inch drills, however for creating a hole, I use metric Cobalt drills. These are easier to get here in europe, they are cheaper and I probably screw them up anyway. Once the hole is drilled I take the slightly bigger correct drill and match drill the hole.

Here is he clecoed Firewall as you can see it has both #40 (chrome cleco) and #30 (copper cleco) holes. Now I can deburr and prime the Aluminum parts.

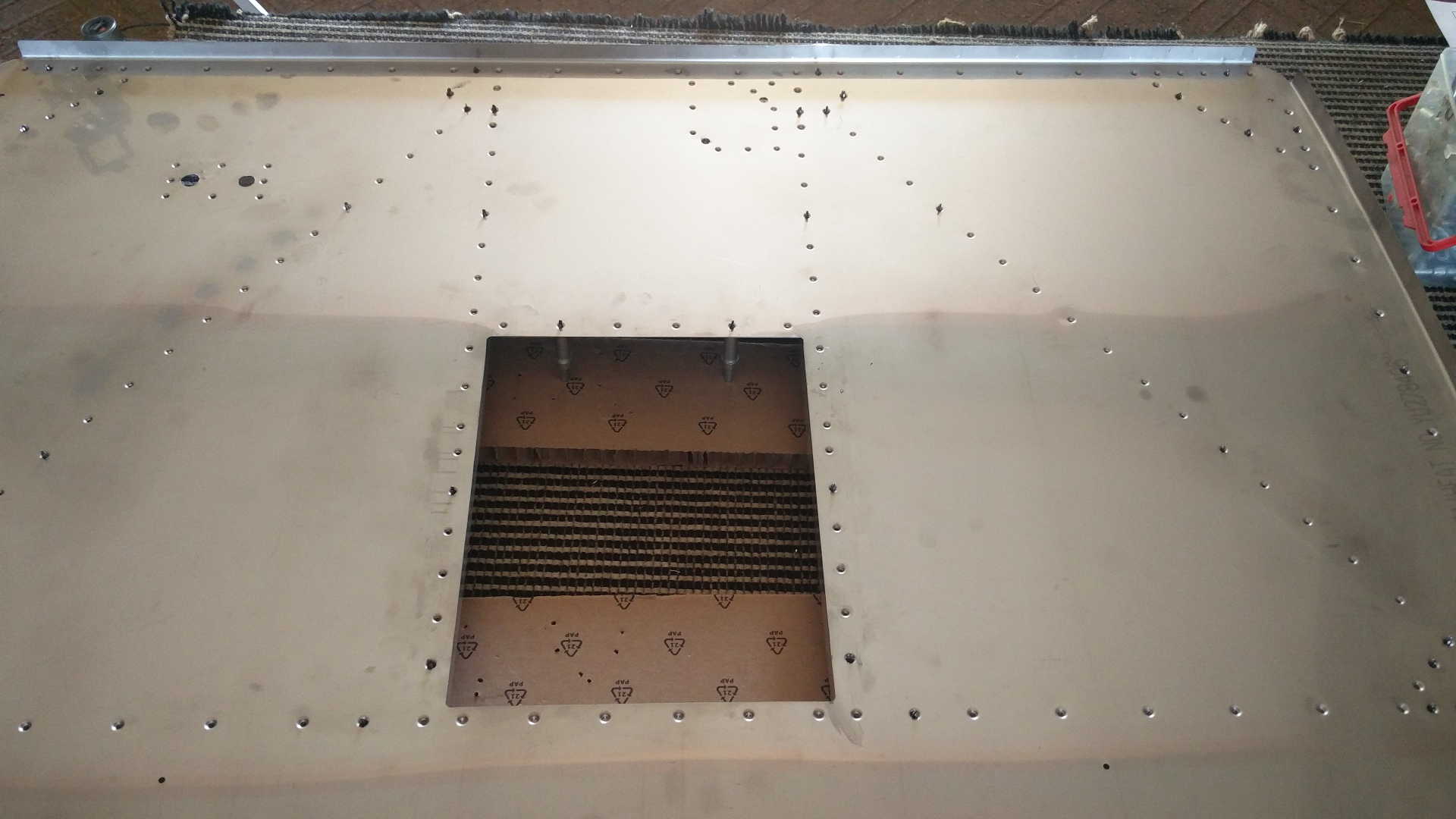

After dimpling the forward side of the Firewall looks like this.

Time: 6 Hours, Rivets: 0/0 (2019-05-26)

Time: 4 Hours, Rivets: 0/0 (2019-06-01)