On Friday the 21nd of February, my dad and I hit the road and drove to Ieper in the South West of Belgium to visit the ULPower aircraft engine factory. There were about 10 people from all over Europe (Germany, Spain, Sweden, UK and Croatia).

We were invited (as potential buyers) for one of their ‘familiarization classes’ at the factory. The reception was very friendly and Evelyne and Patrick made us feel very welcome. After an hour of history and overview on the engines, Patrick showed all attendees around in the factory itself. Stunningly this factory is operated by a single engineer and a completely automated CNC-robot.

At the entrance there where palits with blocks of Aluminum. The robot runs 24/7 and picks Aluminum blocks, places them in the CNC-machine and returns the finished pieces. On the right you can see finished parts, on the left there are different tools for the CNC-machine that are placed in the machine by the robot if it requires to execute a different process.

On regular intervals the engineer requests the robot to pick finished parts and deliver then to him for inspection and measurements. All parts are logged including their measurements and deviations.

The core of the engine is created out of two blocks of Aluminum. You can see a six cylinder in the front and a four cylinder on the back of the palit.

The robot works day and night and the engineer makes sure that before he heads home, all the slots are filled with Aluminum blocks, so the machine can work all night. Obviously the robot is surrounded by storage racks, so no one can reach the robot (or actually the other way around, because I think it won’t even sense it when it decapitates you.

The finished cylinder walls with the cool-fins are stored in a rack with engine serial numbers on them. Besides the CNC production of parts in Ieper, ULPower also has a aircraft engine assembly factory in Oostende (Belgium). This assembly facility takes the parts created in Ieper and build the actual ULPower engines.

The rest of the factory is empty, except for some manual tools and auxiliary parts. However I guess the manual tools are obsolete, because they didn’t run at all.

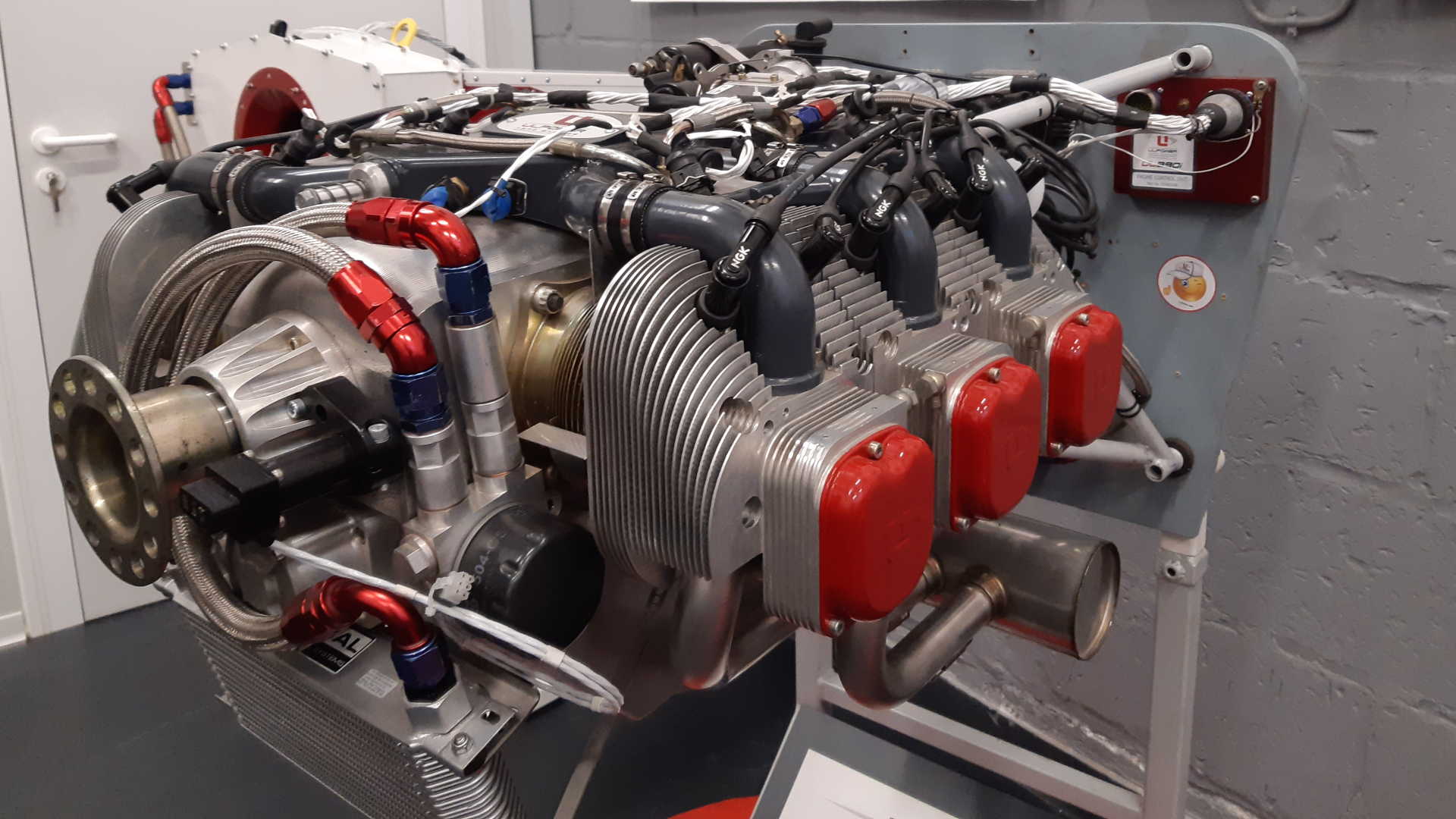

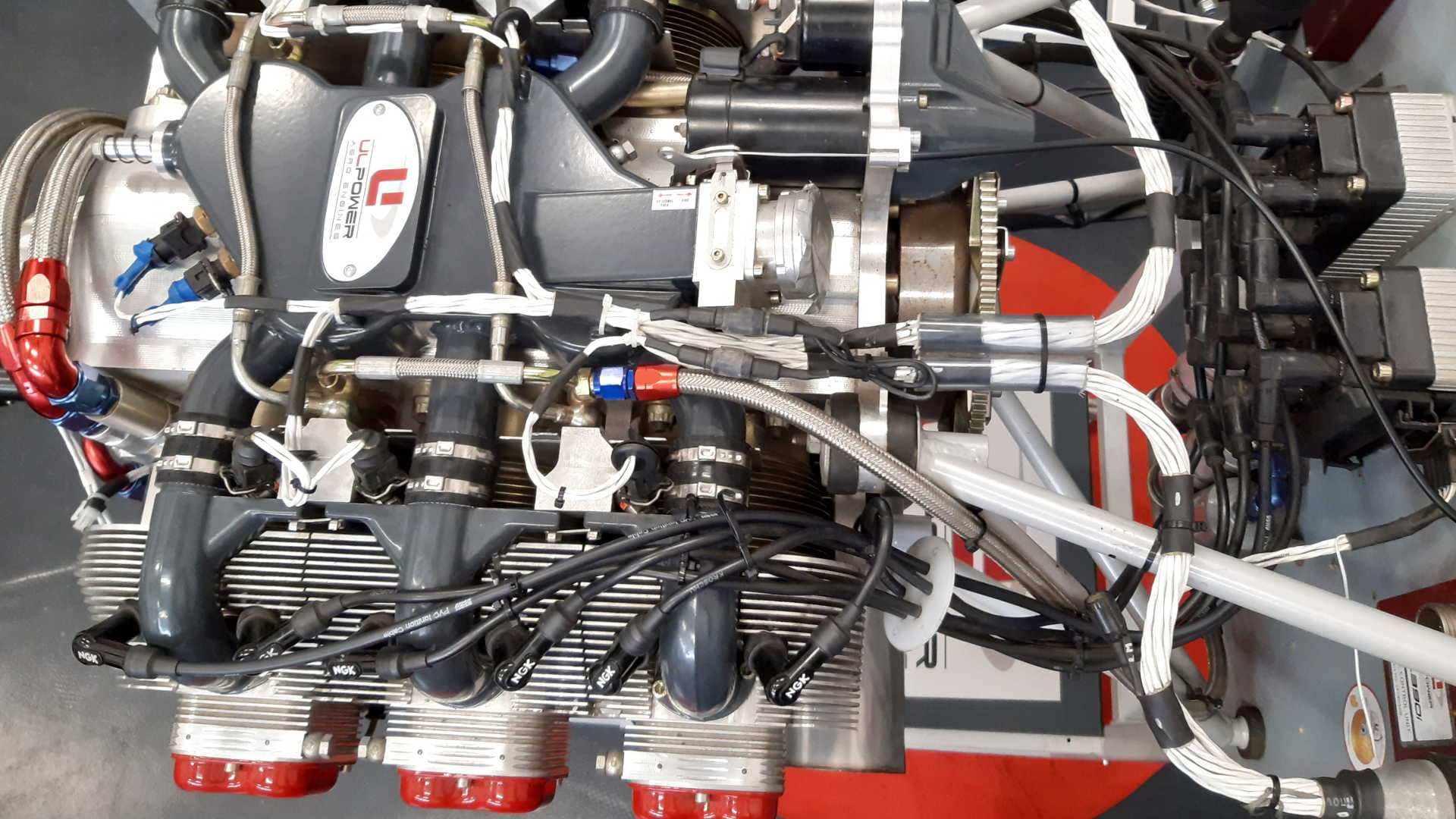

Meet the ULPower 520iSA. It’s a six-cylinder, 108kg, 200hp Lycoming alternative.It has both air and oil cooling and a ECU controlled injection system.

It is the engine I choose for my RV-7 and it looks great.

Time: 5 Hours, Rivets: 0/0 (2020-02-21)

Beste Marcel,

Om te beginnen dank dat je al jou ervaringen deelt via youtube!!!!

Mijn naam is Rob Ronner, ben zelf bezig met het uitzoeken van een geschikt bouw pakket. Volgende week gaan we met de familie naar Italië om daar de Tucano R te gaan bekijken.

Omdat ik liever een ul-power of een lycoming dan een rotax zou willen gebruiken ben ik erg benieuwd naar jou ervaringen.

RV maakt alles pas voor lycoming, wat als je daar van af wijkt? Ben je het wiel op nieuw aan het uitvinden?

Ik ben in contact met de fabriek voor het Tucano bouw pakket en er bestaat de mogelijkheid om deze ook uit te rusten met een ul520.

Mocht de tucano niks worden denk ik dat het ook een RV gaat worden 🙂

Maar goed, eerst maar eens de fabriek in Italië bekijken.

Maar nogmaals, ik kom heel graag met je in contact en ben erg benieuwd hoe makkelijk of hoe moeilijk jou proces was met het pas maken van de ul-power voir de RV en vervolgens de prop erbij te vinden.

Hier mijn mail adres

rob.ronner@gmail.com

nogmaals dank voor het delen van al jou ervaringen op youtube, ik hoop echt iets van je te horen!!!

met hartelijke groet, Rob

Hi Marcel,

I’ve watched the progress of your RV-7 for years and have greatly enjoyed the journey.

I’m looking at building either the RV-15 when they start producing a kit, or the RV-9. I’m looking for a touring aircraft so the 15 is looking very good.

I’m not a fan of the old Lycomings. Nothing against them, just think there should be a better option than a 70 year old design.

Which brings me to my reason for reaching out to you. It seems the UL Power is rapidly growing in popularity, and I’d like to use the 520 in the RV-15 or the 160hp 390 in an RV-9. I know you corrected the CG by shifting the lighter UL 520 about 200mm further forward. However, I’ve read some forums where people suggest that moving the engine forward may affect handing characteristics, like stall recovery, even with the CG correct.

Are you able to tell me if you had any discussions with anyone, maybe even UL Power, about the affects on handing characteristics and the outcome of those discussions? Is that something I should discuss with UL Power?

Cheers and thanks again for the great RV-7 journey 🙂👍

Peter

Hi Peter,

Thanks for your comment. I’m flying my RV-7 for over a year now and have not had any bad experience regarding maneuvers.

I have (deliberately) stalled the plane many times in several configurations and power settings and found no issues with handling.

Like all RV’s the stall is very docile and it just dips the nose and carry’s on.

I had a discussion with Ryan (from Van’s) on this topic (with respect to airworthiness, which is stringent here in the Netherlands)

and the only doubt that we have at this point is what happens in a (flat) spin.

Although the (total) weight is less, the mass is moved more towards the edges of the spin.

However I do NOT have a aerobatic rating, which is on my checklist for 2023.

As soon as I have my rating I will throw PH-MNX in a spin, make a video on it so we can see what happens.

With respect to the 9 or 15, I don’t see any issues, as these are not aerobatic planes. Also I think the rudder on the 9 and 15 are bigger.

More rudder will recover spins more easily.

Conclusion normal flight maneuvers are NO issue, aerobatics you’ll have to check in later when I will cover these.

Cheers,

Marcel