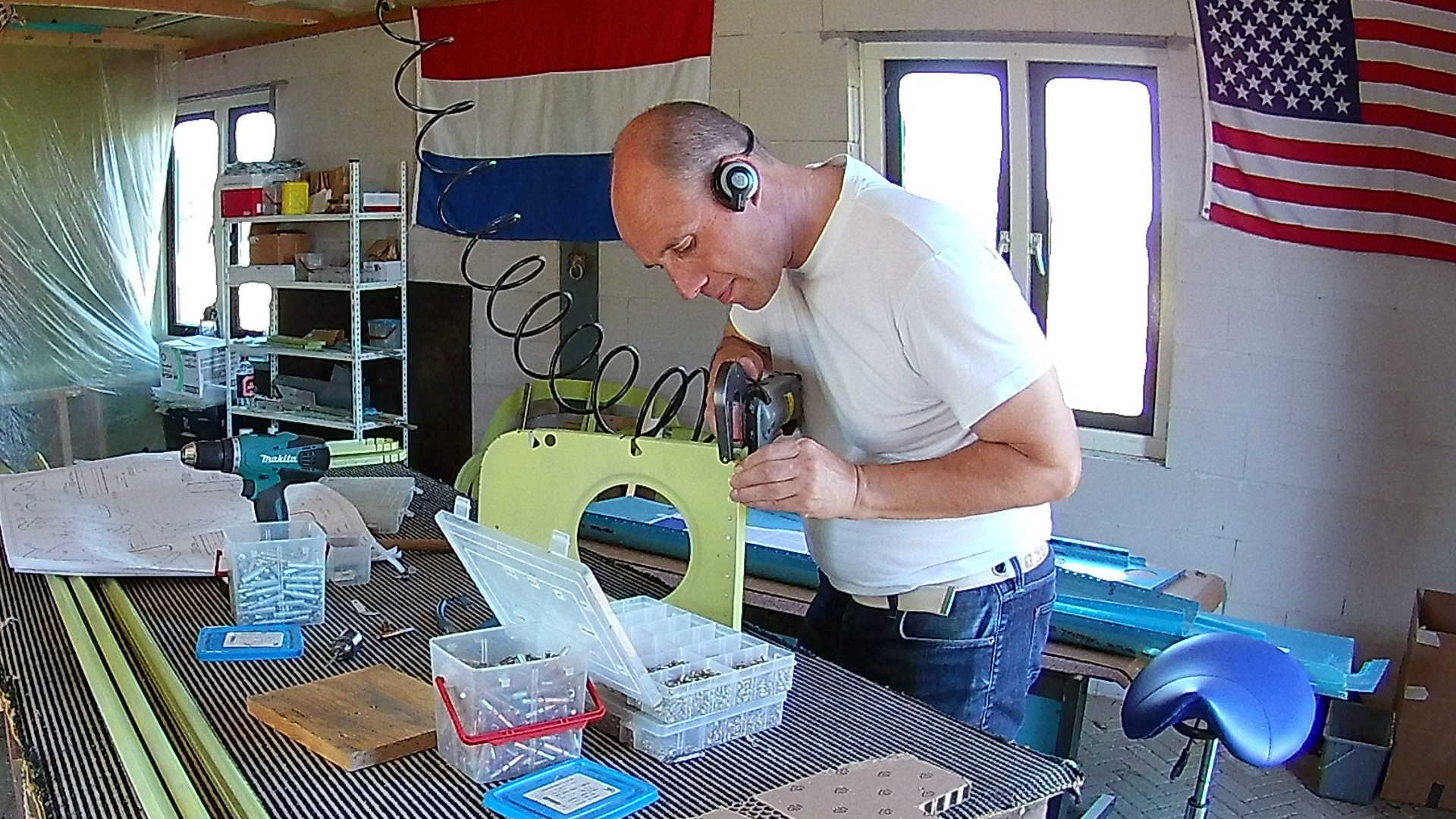

With the Bulkheads and J-channels) primed, I started clecoing and riveting them together.

Starting with the 708 Bulkhead (this is the one aft of the seats bulkhead). The plan says you should NOT rivet the 728 channel (that is the vertical piece), not sure why but let’s leave that clecoed for now.

The next bulkhead is considerably smaller and also should not be completely riveted. Riveting these bulkheads is easy, because I can use the squeezer and it’s just a few rivets.

Next Bulkhead (710) just needs an Aluminum angle attached to it.

The last two Bulkheads are more work, because they consist of two parts. Especially the 711 is more work, since the Horizontal stabilizer (from the Empennage) will be attached to this Bulkhead. Because of the two parts I could only partly use the squeezer.

The next day my Dad helped me with riveting the two small Bulkheads to the tail bottom skin. This skin is thick, because of the tail-wheel construction.

Also this part didn’t fit very well and it required a lot of trimming.

Because I’m building a tail-dragger (tail-wheel model instead of a nose-wheel version), there is some extra work involved for said tail-wheel.

Turns out to be a lot of work, because we spent 3 hours just trimming, fitting and clecoing the tail-wheel bar to both Bulkheads and the skin.

Looks like not much was done, but I was happy with the result.

Time: 3 Hours, Rivets: 52/2 (2019-08-24)

Time: 4 Hours, Rivets: 0/0 (2019-08-25)